Courtesy of Wikipedia, a .30-30 cartridge (center) between 5.56×45mm NATO (left), and 7.62×51mm NATO (right)

I knee-jerk purchased the Marlin 336 (in .30-30 Winchester) mainly due to it’s extremely competitive price tag. The fact that it was a lever gun was also intriguing to me. Lever guns were something I had little experience with, so the whole lever action concept was a field that I was yet to explore. As it turns out, Marlin produce some of the best value “no frills” lever-action hunting rifles on the market and the 336 ended up being a great entry into the world of lever guns.

I had done a little homework and I concluded the 30-30 was a hard-hitting caliber that could cater for all of my needs. The 30-30 (metric 7.62x51mmR) was the US’s first small-bore cartridge designed for smokeless powder. It first appeared around 1895. It’s age means there is a lot of handloading data available. Physically, the 30-30 cartridge is comparable in length and caliber to the 7.62x51mm NATO (aka a .308). In saying that, it performs vastly differently to your average 308. Let’s deviate for a moment to compare the 30-30 against the 308.

One thing I learnt pretty quickly was that generally speaking, lever guns require FN (flat-nose) or FP (flat-point) projectiles. This is due to the nature of the tubular magazine running underneath the barrel. Rounds are inserted one-behind-the-other, meaning the tip of each bullet is pressed against the primer of the bullet in front of it. If you were to use pointy SP (spire-point) bullets in a tubular magazine, the recoil from the rifle can cause the rounds to butt against each other, causing detonation in the magazine. See the problem there?!

Being limited to FN bullets means you won’t achieve the long-distance performance comparable to a 308 (which is designed to, and generally uses, SP projectiles combined with longer, heavier barrels). In more complex terms, the ballistic coefficient and flight characteristics for a 308 projectile is generally far superior to that of a 30-30 projectile. Given this fact, lever-guns are designed as lighter, close-range, hard-hitting, rapid-action carbines. Focus is placed on shooter ergonomics rather than long range performance. Basically, the 30-30 cartridge is ideal for a light, easy-handling rifle that allows for a lot of energy to be delivered to close-range targets in a quick succession of shots.

What choose lead?

There’s no denying, cast-lead is comparatively cheap. We’re talking in the realms of 1/5th (or less) of the price of commercial semi-jacketed projectiles, and even cheaper if you cast yourself. And at shorter ranges, they’re also as accurate, if not more accurate than modern factory ammo. So you might ask, why would you even consider factory semi-jacketed? Besides the obvious convenience factor, hotter jacketed loads excel when it comes to trajectory, stopping-power, longer-range performance and minimizing barrel fouling. Basically, they are simpler and easier to use. The drawbacks of such loads are they generate a lot more heat. Fast hunting loads heat a light sporter barrel very quickly, meaning stringing long groups of shots together will result in poor accuracy. These upper-limit loads are also much harder on your barrel and your shoulder, so if you intend on doing any amounts of target practice, ideally you should stick to softer plinking loads.

Ok so back on to lead; gas-check-less (checkless) cast-lead is perfect for varminting and plinking (at close ranges), but is really not appropriate for classic, medium to large 30-30 game (like deer). The reduced charge lead loads lack stopping power, and have a much more arced trajectory, meaning you need to make significant sight adjustments / holdovers in the field to account for that excessive bullet drop. On the contrary, hot factory ammo has a much longer point-blank range. Making intensive holdover calculations whilst hunting (when you often have a short window of time to take a shot) is something you should try to avoid.

Five beveled “checkless” lead projectiles next to two gas-checked lead projectiles ( right ).

Due to its soft, malleable nature, raw lead also has a tendency to leave a nice smearing of lead deposit down your barrel after repeated shots. This will quickly foul things up, resulting in progressively decreasing accuracy. Not to mention it’s tedious to clean after a comparatively small number of shots. Generally speaking, the faster you push a lead projectile, the more leading you’ll get. One obvious suppressant is to use some sort of lubricant on the projectiles, but this can be time-consuming. Thankfully, these days there’s an easier alternative: introducing the polymer/powder “coated” lead projectile.

The idea of polymer coating is to provide integrated lubrication to protect from leading. This acts to seal and lubricate the naked lead (removing the need to secondarily lubricate the projectiles). The coating restricts the amount of lead that rubs off as the round moves down the barrel. A lot of companies claim their “coated” projectiles can be pushed in excess of 2000fps without excess fouling – this may be true, but you’d definitely need to include gas checks at those sorts of velocities. Without gas checks, it’s to stick to lower velocity lead load/single-action data to maintain consistent bullet obturation. A good rule of thumb is around the 1600fps mark for checkless lead, give or take.

I noticed a lot of people throwing around the idea of “hard-cast” lead projectiles. “Hard-cast” (vs raw lead) is usually a mixed alloy that allows for a harder material. Brinell hardness for “hard-cast” projectiles is usually in excess of 15 BH, which is notably harder than raw lead ( which comes in around 8 BH ). A harder alloy (in theory) means less leading and thus potentially higher velocities ( without excessive fouling ). In our case however, without gas-checks, brinell hardness is still not really a huge factor. Sure, a harder projectile may result in less fouling, but without gas checks, even “hard-cast” projectiles can’t be pushed at anywhere near jacketed velocities.

To reiterate, if you push any kind of checkless lead too hard, and gas will “cut” around the sides of the projectile upon pressurization. This will cause the projectile to “rattle” down the barrel, tumble through the air, and keyhole (hit sideways) all over the target. When I first tried shooting lead, I used too much powder for the soft lead. This resulted in extremely poor accuracy, i.e. the rounds weren’t stabilizing. If you’re having trouble with accuracy, look for signs of keyholing, i.e. non-circular holes.

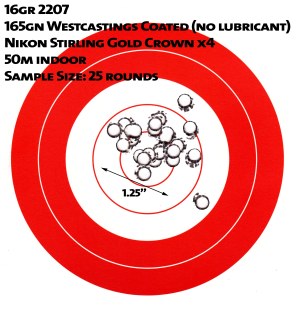

For Australian customers, there are a few projectile manufacturers who sell beveled, checkless, “polymer-coated” .310″ 165gn RNFP 30-30 hard-cast lead projectiles. Due to the coating, these indeed do not require lubrication (although lubing may well give you a slight improvement in accuracy), and (generally) so long as you keep your velocity below 1600fps will give you good accuracy out of a Microgroove 336. They are also bags of fun to shoot and extremely cheap to run; great for varminting or honing those off-hand plinking skills.

What powder should I use?

Down here in Australia, most use (and supply) ADI powders. ADI provides load data on their website. Don’t forget to check out the single action section when looking for reduced cast-lead loads. They also provide an equivalency chart, which shows how ADI powders compare to other (non-Australian) powders. DISCLAIMER: This load data should be roughly translatable across equivalent (non-ADI) powders, however as stated on ADI’s website, there could be up to 5% variance, so be careful. If you’re unsure, do more homework first and verify your new load from another source before reloading.

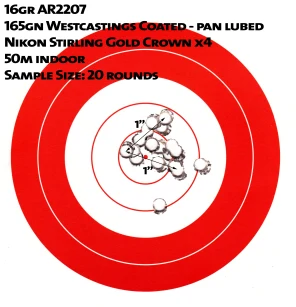

With the disclaimer out of the way, lets talk about sending lead through the Microgroove 336. Cast-lead projectiles definitely like a reduced load of a powder around the middle of the burn-rate spectrum. Both AR2207 (equivalent to H4198) and AR2206H (equivalent to H4895) are fairly accurate under lead, although AR2207 is by far the most popular of the two down under. I was able to achieve a consistent 2.0moa with a reduced load of ~16.0gns of AR2207. AR2206H yields around 2.5moa with ~18.5gns of (over a 165gn RNFP lead projectile). These two loads will give you around 1500fps. You’d might be able to tighten these up slightly with some 1/10th gn ladder testing.

AR2207 is the most popular lead powder down under. around 16.0-17.0grs is the sweet spot. This large sample size group was achieved by pan lubing the coated projectiles.

Same load as above, but no lubing (just the standard coating on the commercial projectile)

This 5 shot group was in fact achieved with a peep sight; get rid of those factory dovetail sights and heavy factory trigger ASAP.

It’s a bit cheeky of me to claim that “flyer”, but the 336 tends to group pretty tightly followed by a pesky flyers as the barrel heats up. That’s why shooters tend to broadcast 3-shot groups; in reality I think you need 5-10 to claim any sort of inherent accuracy.

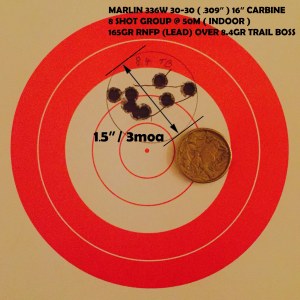

ADI’s/IMR’s new Trail Boss powder is also an option for lead. Trail Boss is designed to be used with lead; with an emphasise placed on economy. If you can get your hands on it, it’s at least worth a try (or the comparable Unique powder) for reduced lead loads. Trail Boss granules are physically less dense (i.e. more volume for weight) than your traditional smokeless powders, meaning the cases are a lot fuller for the equivalent charge. This (theoretically) results in a more consistent burn. You read in a lot of places a 165gn cast-lead projectile over 9.0gns of Trail Boss, but in fact my 336 groups noticeably tighter at slightly less than this, around 8.4gns seems like the sweet spot. This will give you around 1150fps. Again, I strongly recommend doing some ladder testing around this area to identify precisely what your rifle wants.

An 8 shot, cast-lead, Trail Boss group. This was shot rather quickly through a hot, dirty barrel. Realistically, this is the sort of accuracy a 336 can constantly plink, disregarding fouling and barrel heat.

A surprisingly tight, 200 meter group shot off a rudimentary front rest (with some pretty cheap optics). This was shot through a clean, cold barrel. Whilst the 336 won’t consistently group this tightly, it does show how (practically) capable a modern 30-30 can be (with the right load and a decent replacement trigger). Who says a lever-gun isn’t accurate?

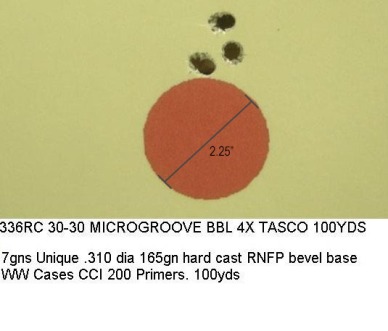

EDIT: Apparently around 7.0gns of Unique under a 165gn cast projectiles is also accurate; quite comparable to Trail Boss. This stunning 1moa group of a cast-leads was shot by a moderator on http://www.marlinowners.com:

Hunting / Semi-jacketed Loads

Generally speaking, for semi-jacketed hunting projectiles, the modern 30-30 demands a medium-burning powder. For hunting at longer distances, you probably should choose the 150 gn for higher speeds and less drop. For closer-range brush hunting, the heavier 170gn round nose (or flat nose) are more tolerant to deflection from vegetation, not to mention harder-hitting. Both of these projectiles are more than adequate for true medium game. DISCLAIMER: Especially for your full power loads, ALWAYS ensure a proper crimp. Without it, projectiles in the magazine can seat deeper and deeper after each shot, equating to a progressively smaller ignition cavity that can ultimately result in a catastrophic detonation.

The new 160gn Hornady FTX “Leverevolution” projectiles over 32.0gns of AR2208 (similar to H335) would be a solid start. They have a gummy spire-point and thus a higher ballistic coefficient than your traditional FN projectile, meaning a flatter trajectory and a bit more stopping power over those medium distances (200yd+). A real no-brainer, but not necessarily any more accurate than your traditional FN projectiles. Nevertheless the fancier 160gn Hornady FTX “Leverevolution” are probably best paired with HODGDON LEVEREVOLUTION POWDER. There is load data on the side of the bottle itself; 35.5C under said projectile will spit them out at 2300fps which is fast for a 30/30.

My personal favorite is a 150gn FN over 34gns of AR2206H (aka H4895) – this will give you about 2200fps and is pretty flat even out to 200m. The 150gns (with a cold barrel) will shoot a consistent 3-shot group of around 2.5moa. Apparently 30.0gns of Bench Mark 2 (aka IMR3031) and 35gns of H335 work pretty well with the 150gn projectiles too; although please double check your manuals first for these two powders, as I’ve never personally used them. Hand-loaders swear by these combos and I’m pretty sure with some 1/10th gn ladder testing you could identify a damned-accurate hunting load that would group close to 2moa.

I’ve also experimented with 23gns of AR2207 (aka H4198) under a modern jacketed pill. It’s not the most suitable powder for jacketed (a bit fast-burning for full-power 30/30 loads), nonetheless yielded good accuracy at around 2100fps.

EDIT: Another amazing 1 moa group using a 150gn FP semi-jacketed over 35gns of H335 (similar to AR2206H), again shot by a moderator from http://www.marlinowners.com:

Copper Plated Bullets Loads

Berry’s copper-plated 150gr 30/30 bullets are extremely accurate over 21gns of AR2207 (aka H4198), yielding approximately 1850fps. The only catch is they must be kept under 1900fps, and they will not expand on game. Save them for varminting or the range.

Berry’s 150gr 30/30 bullets are extremely accurate over 21gns of AR2207 (aka H4198)

Further discoveries when reloading for the 30-30

Lead shaving when seating

When seating the lead projectiles, I noticed some of the lead was being shaved-off due to the tight mouth fit. This should be avoided by using an expanding die. People suggest chamfering the mouth further, but this will only reduce the lifespan of the brass. I try to keep my chamfering to a minimum. The Lee Universal Expanding die seems to do a good job of belling the mouth slightly to allow the projectile to seat down a few millimeters (before applying your press). There are other alternatives, search “expanding die” for more info.

Hornandy “Built-In Crimper” not crimping adequately

The Hornady 2-set die is marketed to have an in-built crimper. I found that for the 30-30, this crimper was not adequately (and consistently) crimping the mouth into the cannelure. In fact I was having to increase the crimp pressure so much, it was at times denting / buckling the shoulder of the shell when seating. The solution to this was to use a separate crimping die, I found the Lee Factory Crimp Die to be an excellent tool for achieving a nice “factory crimp”. A good crimp is essential to achieve a consistent shot start, i.e. a consistent, required build up of pressure before the projectile leaves the mouth of the brass.

Over-sized ( 0.001″ – 0.002″ larger ) projectiles in a Marlin “Microgroove” barrel

A lot of people say that the Microgroove barrel likes a slightly over-sized lead projectile (approximately 0.001″ – 0.002″ larger in diameter) to help with obturation. At this stage I cannot conclusively comment on the significance of a slightly larger projectile in a Microgroove barrel, you would really need to slug your barrel before running over-sized projectiles, something I am still yet to do. The lead projectiles I buy are marketed to be .309″ and they give me good accuracy. One thing is for certain though, when using a any powder, increasing the load will not stabilize even an over-sized lead projectile – the velocity has to be around 1400 fps to prevent gas-cutting of the soft-lead, and really suits the sharp pressure wave produced by a fast burning powder.

I have fired 100’S of rounds in my 30/30 using the HRBC 165 gn cast bullet and 16 gns of adi2207.

My 12 yo son likes this load, as it has little recoil.

LikeLike

Hi Harold, I’m glad to hear someone else is having fun with the 30/30 HRBCs! I most definitely agree that a reduced load of AR2207 (and also AR2206H) seems to work well with the 165gn HRBCs – I’ve achieved some superb accuracy with both of these powders. The reduced recoil also equates to the perfect plinking round; so for a variety of reasons, it’s what I routinely practice with at the range. Another bonus is that reduced loads prevent beginner-shooters from developing any kind of flinch from the normally heavy-recoiling .30 cal carbine.

My only observation with a reduced load of AR2207 (or AR2206H) is that they only partially fill the shell volume. This is not ideal, as theoretically the burn could be inconsistent relative to how the powder is positioned in the case. Handling a cartridge in different ways prior to loading can in fact lead to different muzzle velocities (and therefore, theoretically, different POI’s). I’ve also read about stories of catastrophic failure due to an unusual pressure wave forming from a very light load in a large case (like a 45/70). Here is a really interesting article relating to this issue, and part of the reason I prefer to use ADI’s Trail Boss powder over these traditional powders (for reduced loads). Trail Boss in contrast fills considerably more volume relative to its weight; 9gns fully fills the case yet outputs a mellow muzzle velocity of ~1200fps!

In saying that, I think any kind of failure would be highly unlikely in a 30/30 (with these two particular reduced loads/powders), as they both fill more than 50% of the cavity. The powder will always (to a lesser or greater degree) be in contact with the primer. Furthermore, I’ve never experienced (nor heard of) any failures from a reduced 30-30 load; worst case would be a few annoying flyers (which I feel I have personally experienced with reduced loads of 2207 and 2206H). If you become worried about this issue, you could always consider using some sort of cartridge filler to guarantee consistency. Here is another interesting read about simply using tissue paper as a filler.

Though if I had to choose between AR2207 & AR2206H, I’d have to say 2206H is slightly more versatile than 2207; great for cast lead and jacketed projectiles. 34gns of 2206H under a Sierra 150gn FN is also an exceptional hunting load for the 30-30; fairly flat even out to 200m yet still very hard-hitting and accurate. More than adequate for all Australian game.

LikeLike

Interesting article. I’ve got a 336TS with 18.5inch barrel. Thinking of using 2206h with the 170gr Sierra Flat point bullets. I put XS aperature sights on it but not very good for load development, as the aperature is so big, there is as much variation in sight position as there is in the powder steps.

LikeLike

Hi Jonathon thanks for the feedback. In fact I’ve learnt even more about my 336W since writing this article a while back, I’d really like to refactor it some more when I get the chance. I honestly think modern microgroove Marlins aka “remlins” prefer a 170gr projectile over a lighter projectile, so I think you’re onto something with your Sierras! One thing I learnt not so long ago was the tightness of the barrel bands and screws can affect accuracy, particularly when the rifle starts to warm up. I sanded my forend back a little and then re-coated with some tung oil so the forend band fits slightly looser now. This helped me realize that constant 2moa for target work. And I totally agree about your sights; it’s definitively best to develop your loads with a scope if that’s an option. These days I run a williams FP-336-TK receiver with a Lyman 17AHB front peep, this gets me to 300m with a 1500fps cast-lead projectile with acceptable consistency. Good luck!

LikeLike

Great article! I’ve been looking for load data for the ACME 135gr polymer coated lead bullet in a 30-30. I’m in the States, so I’ve got easy access to powders. Right now, our political environment has made reload components, particularly primers nearly impossible to get, but I’ve got quite a few stockpiled. 😁

If you have any thoughts on what to try, I’d love to hear them. My reloading buddy has an old chest freezer where he stores powder, so I have access to a little bit of everything to try.

Shalom

LikeLike

Gday mate. Indeed there are powder shortages everywhere in this climate – even “down under” pistol powders are currently on the ropes. One powder which is particularly popular for slinging lead is IMR Trail Boss – you certainly need to give that a go. Otherwise, if you a benching the rifle and chasing that very last drop of accuracy, powders around the H4198/Reloader 7/IMR4198/W680/Tu 2000/N200/N130/AR2207 region are good for the 30-30. The coated-lead is “slipperier” than normal jacketed thus demands a faster-than-usual powder. You could also go a little faster with H4227/H110/IMR4227/W296/R-123/AA1680/N120 but be very careful with pressures. Take extreme care not to double-charge, the results can be catastrophic. Try and find listed data with any of the aforementioned powders; that’s the sensible option. It doesn’t have to be exactly a 135gr lead pill, but close-to. Er on the conservative side when you are unsure. Cheers, Jim.

LikeLike

Okay, thank you!

LikeLike

22 Cowboy, once you have decided on what powders / load, I can run the data through Quickload software to double check the safety before you shoot it. Just let me know.

LikeLike